It is not the same to manufacture steel for a dock, for the bridge of a train, for an oil tanker chain, for the hull of a ship, or for the fuselage of an aircraft. The qualities to be controlled are, among others, its resistance, its elasticity and its hardness. These properties can be modified by alloys made with other materials.

Alloys and the rate at which they change with temperature provide us with a wide variety of steel types.

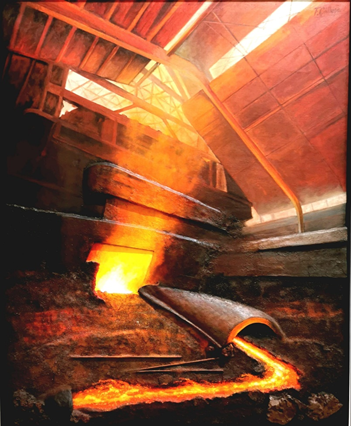

The combination of iron, carbon and temperature determines whether we have steel or cast iron in front of us. Steels are alloys with less than 2.06% carbon and castings if the carbon content is greater than 2,06% and less than 7%. Furthermore, subjecting it to high temperatures allows us to achieve the steel microstructure with the desired properties for a specific industrial application.

Next to the microscope you have samples of ferrite, cementite, perlite, austenite, ledeburite, martensite and widmanstätten. The latter is iron from a meteorite that fell thousands of years ago in Cape York, Greenland. Doesn’t the etymology lead us then to «sidereal» meaning «coming from the stars»?