Before converters made it possible to manufacture large steel parts, large iron structures were made of puddled iron. This process, invented by Cort in 1783, received the name puddling from the English “to puddle”, and until the end of the 19th century, this was the only method used to obtain laminated iron for large structures.

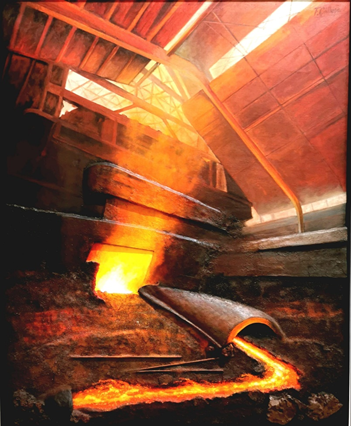

Puddling consisted of passing the cast iron, before it cooled, to a closed reverberatory furnace, where it came into contact with scrap and slag of iron oxide and where impurities, carbon and sulphur burned. This mass of incandescent iron was removed by hand by the workers called puddlers, equipped with long bars, which were introduced through a small opening in the oven door, and which had to be changed every five minutes because they were too hot.

The puddling required maximum strength, resistance to fatigue and heat, attention and intelligence, there being no industrial operation that required such hard muscular efforts and in such exhausting conditions. The work was carried out next to a furnace with a temperature capable of melting iron, between 800 and 1200 °C, stirring in all directions with an iron instrument, a mass of pasty metal that weighed more than 150 kg and keeping the eyes fixed, blinded by the incandescent light of the iron, which produced cataracts and blindness. Most of the workers engaged in puddling lived only until they were 45 or 50 years old.

The process survived for many years despite the emergence of converters. In 1888 the Eiffel Tower was built with puddled iron and the Vizcaya Transporter Bridge was also made with puddled iron in France’s Le Creusot ovens. In 1890, Bilbao’s Altos Hornos had 16 puddling ovens and 3 pylon hammers, and La Vizcaya had 4 puddled iron ovens, and a pylon hammer.